Articles

April 30, 2024

The Australian Building Codes Board (ABCB) has limited the allowable lead content in plumbing products, which contain copper alloys and are intended to be in contact with drinking water. From 1 May 2026, licenced plumbers cannot install products with a weighted average lead content of more than 0.25% in a plumbing system used to convey drinking water.

Contamination of drinking water by metal, including lead has been extensively studied since it’s discovery as some of the first known environmental hazards. There has been growing concern about the presence of lead in our drinking water due to the dangers associated with consuming even small amounts of it leading to health issues. These issues are preventable by eliminating exposure to lead.

A small amount of lead is currently used in the manufacture of some copper alloy plumbing products. While these products are safe, the recommendation from health officials is to reduce exposure to lead where possible. Transitioning to Lead Free plumbing products will help contribute to improved public safety.

Products that do not conform to the new lead-free requirements outlined in the National Construction Code (NCC) 2022 Volume Three (the Plumbing Code of Australia) will not be authorised for use in contact with drinking water. These include fittings, valves, backflow prevention devices, taps, mixers, water heaters, water dispensers (boiling and cooling units) and water meters.

The term ‘Lead Free’ is defined in the NCC as “where a plumbing product or material in contact with drinking water has a weighted average lead content of not more than 0.25%, as determined in accordance with A5G4(2).”

In 2018, the ABCB commissioned Macquarie University to determine to what extent plumbing products contribute to lead levels in drinking water. While the study has determined that Australian water is of high quality, it also determined copper alloy plumbing products can potentially leach lead into drinking water.

Following this study, Clause A5G4 of NCC 2022 Volume Three (Plumbing Code of Australia) was updated to specify that “all copper alloy plumbing products in contact with drinking water must limit the allowable lead content of copper alloy plumbing products in contact with drinking water to a weighted average lead content of not more than 0.25%.”

The standard was set at 0.25% weighted average in recognition that it is not possible to source 100% lead free raw material. This also ensures uniformity with the international market for lead free copper alloy products.

As a plumbing supply manufacturer, we are being proactive in transitioning our entire range of water hoses to lead-free water hoses. Rolling this out in 2024, ahead of the required deadline, will enable suppliers and plumbers to install our product into lead free plumbing systems.

Bromic water hoses have brass connections, which is a copper alloy. As such, our products have undergone testing for recertification and our hoses remain WaterMark approved to AS/NZS 3499 and comply with the Lead Free requirements.

The transition to lead-free is a positive step towards improving the safety of our drinking water. At Bromic, we remain dedicated to providing our supply partners the highest quality plumbing products which meet and exceed Australian & New Zealand standards.

Our water hose materials have been upgraded to comply with the updated standard, ahead of deadline, with the variety of connection sizes and hose lengths on offer remaining unchanged.

– Iain Richard, General Manager

As part of this change, we are taking the following steps:

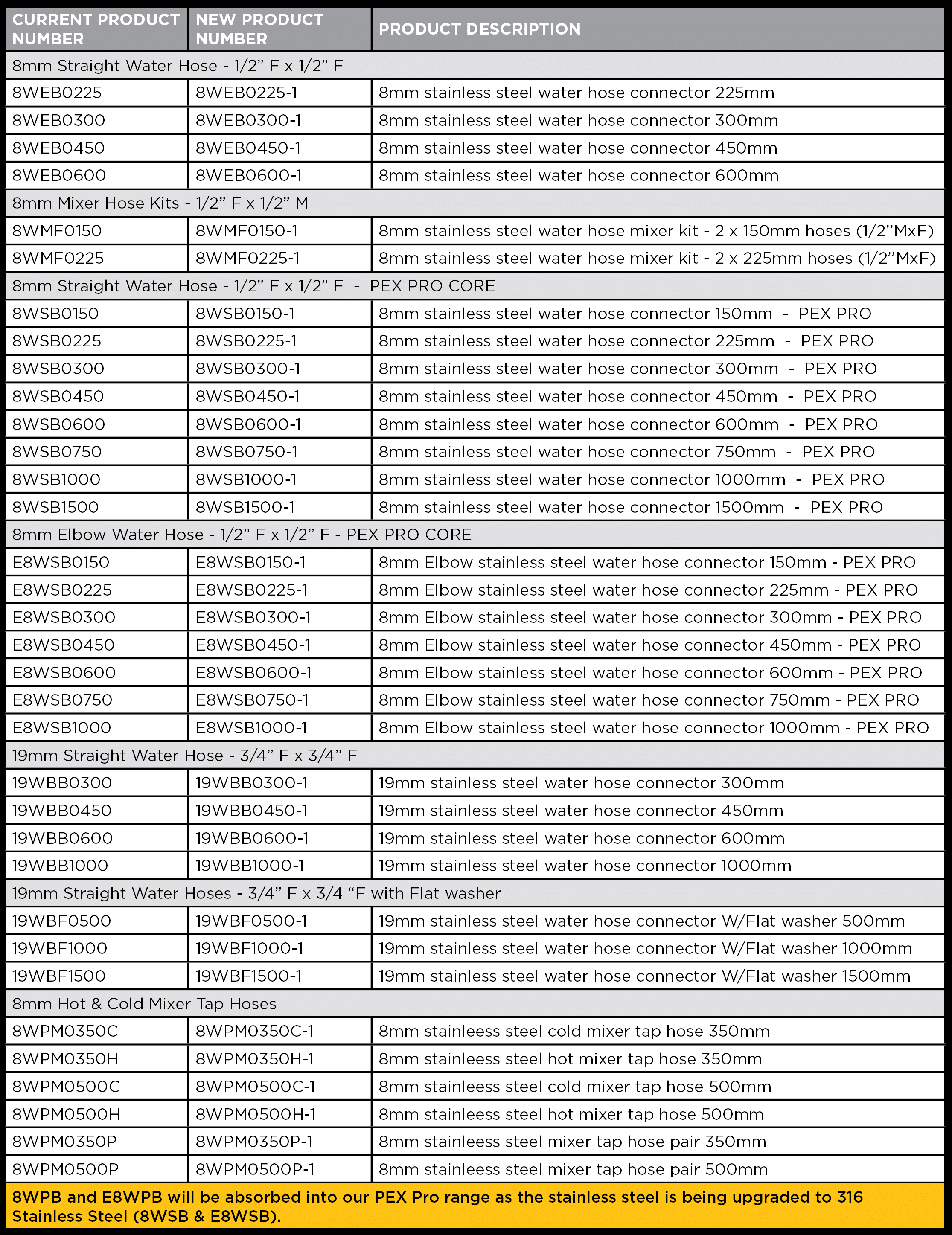

You can view a comparison list of Bromic water hose old vs new product codes at the end of this article.

Bromic Water Hoses are WaterMark approved in accordance with AS/NZS 3499.

Bromic ‘Quicky’ stainless steel braided EPDM water hoses are manufactured with a rubber core covered with a marine grade stainless-steel braid. These water hoses are durable, flexible and resistant to harsh conditions.

Our PEX Core range are manufactured with an extremely high-density polyethylene inner core covered with a marine grade 316 stainless steel braid. These hoses are more durable than standard EPDM hoses, meet the highest mechanical and hygiene standards, and are backed by a 15yr Warranty.