Favourites

Sign in to your account

By adding to Favourites, you can…

- Save products or resource documents you view regularly

- Save time with quick access to frequently viewed items

Please sign in or create an account to add to your Favourites.

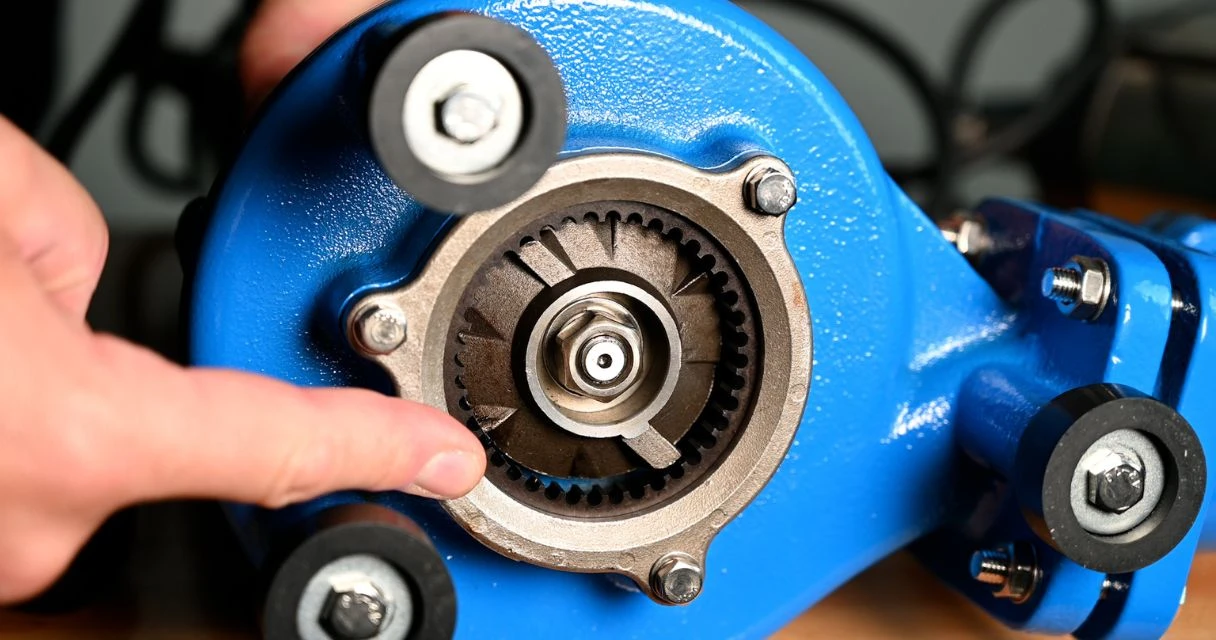

If your auto regulator is not switching over, we recommend looking at the indicator first.

The indicator at the top of the gas regulator indicates if the gas bottle in use contains gas or is empty.

When the indicator is green, the regulator is ON and the gas bottle in use contains gas. When the indicator is RED, the cylinder it is pointing to is empty and the internal valve has switched over to use the other cylinder.

Please note, the indicator only indicates the contents of the cylinder that it is “pointing to” or “in use”. This means that the indicator can show RED when reading the first empty cylinder, even when the second cylinder has gas and is in use.

To accurately check the regulator/indicator is working – only connect or turn on one cylinder at a time and check if it is green or red and if there is gas at the outlet.

To select the right heater, consider the volume of the room that you require heating. The larger the room, the higher KW output required to heat the room.

| Model | Minimum room volume (m3) | Heat Output (MJ/h) | Airflow (m3/H) |

|---|---|---|---|

| HF15 | 270 | 54 MJ/h (15kW) | 500 |

| HF20 | 360 | 72 MJ/h (72kW) | 500 |

| HF30 | 540 | 108 MJ/h (108kW) | 1000 |

| HF50 | 900 | 170 MJ/h (170kW) | 1000 |

The Oxyset uses a mixture of Map-Pro and oxygen gases. The ratio of the mixture affects the flame temperature, but when the ideal mixture occurs so that a blue flame is present the flame will have a temperature of up to 3000°C (5400°F).

Keep your clients happy with long-lasting installations. Read our blog post on common mistakes that lead to burst water hoses.

All Bromic “Quicky”, PEX Mixer Tap, PEX and PEX PRO™ flexible water hoses are suitable for use with heated water up to 70°C @ 1000kPa and cold-water supplies @ 1200 kPa.

At Bromic, we are proud to offer a warranty on all our “Quicky”, PEX and PEX-PRO™ flexible water hoses. Our PEX-PRO™ range is backed by an industry-leading 15-year warranty for extra peace of mind. Bromic “Quicky” Water hoses offer 12 months warranty and our PEX hoses (including mixer hoses) offer 10 years of warranty.

Yes, the Bromic PEX Mixer tap hoses are manufactured with the same stainless steel braid and PEX core as Bromic PEX hoses, making them burst proof. The only difference is the red and blue stripes integrated into the braid to distinguish between hot and cold water hoses.

Whilst Bromic “Quicky” water hoses are manufactured with a rubber core, Bromic PEX PRO™ hoses are manufactured with an extremely high-density polyethylene inner core, making them 100% burst proof*. They are also made with a marine grade 316 stainless steel braid that is highly resistant to rust and corrosion.

| Bromic ‘Quicky’ Water Hoses |

Bromic PEX PROTM Water Hoses |

||

|---|---|---|---|

| Core Material | Rubber | Extremely high-density polyethylene | |

| Braid Material | Stainless steel braid | Marine grade 316 stainless steel braid | |

| Features | 100% burst proof* rust proof |

||

| Warranty | 12 months | 15 years |

*Rated working pressure not to exceed 1400 kPa

According to new research released by general insurer IAG

Push-fit pipes are quick and easy to install and can be easily separated. Solvent-weld pipes use solvent cement to make a strong joint, making them suitable for permanent fixtures.

Push-fit connections connect with push-fit pipes and solvent-cement connections connect with solvent-weld pipes. Some valves come with a removable adaptor that allows it to fit either connection, for example on the Bromic Air Admittance Valve 110mm.

To choose the right air admittance valve, you’ll need to know the fixture unit of the pipe and the airflow capacity required. Read more

| Properties | Air Admittance Valve 110mm (SKU: 1210702) | Air Admittance Valve with Adaptor for 32-40-50mm (SKU: 1210701) |

|---|---|---|

| Recommended Application | Discharge stacks up to 45 metres or 10 storeys high | 32mm and 40mm for use as a connection to waste pipes to prevent water loss from trap seals. 50mm is for use on branch discharge pipes |

| Connection | 110mm push-fit connection 82mm solvent cement connection | 32mm, 40mm and 50mm solvent cement connection |

| Airflow Capacity | 108.32l/s | 10.1l/s |

| Maximum Unit Loading | Pipes – 19,799 fixture units Stacks – 1230 fixture units | Pipes – 172 fixture units Stacks – 10 fixture units |

| Temperature Range | -20°C to +60°C | -20°C to +60°C |

STILL HAVE QUESTIONS?

If you have searched our website, document library & FAQs and haven’t found the information you need, please contact us to resolve your query. This will allow us to continually improve the data we share here and elsewhere on our website.